Original blog by YUFA Polymer Products Co., Ltd.

�� Production Site: Shenzhen, China

�� info@yufapolymer.com | �� www.yufapolymer.com.

⏳ 1. Why Conductive EVA Foam Is Needed in High-End Industries

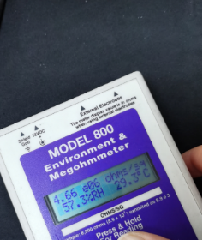

As semiconductor chips and optical modules become smaller, faster, and more sensitive, the risks associated with electrostatic discharge (ESD) grow exponentially. In these industries, even a microsecond of uncontrolled static charge can permanently destroy an IC or impair a laser diode.

Conductive EVA foam (surface resistance: 10³–10⁶ Ω) provides a permanent, low-resistance path to ground. Compared with anti static EVA foam (10⁵–10⁹ Ω), it offers a faster and more reliable discharge, which is critical for semiconductor packaging and optoelectronic device protection..

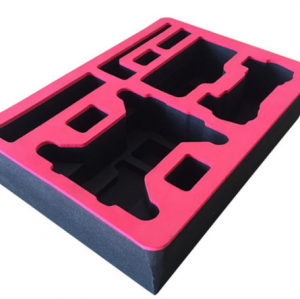

�� 2. Typical Applications of Conductive EVA Foam

Conductive EVA foam is widely adopted in industries where static safety must be absolute:

· Semiconductor packaging – For wafers, ICs, TDMA network cards, and AI chips.

· Optoelectronic modules – Safeguarding optical transceivers, LD/PD chips, and laser assemblies.

· Precision PCBA handling – Protecting exposed circuit boards in testing and transport.

· Robotics & AI equipment – Conductive EVA trays for camera modules and robotic sensors.

· Cleanroom logistics – As conductive cushioning material in returnable containers.

In all these cases, conductive EVA foam ensures both cushioning and controlled ESD protection, making it indispensable for advanced manufacturing.

⚙️ 3. Customer Pain Points Solved

Electronics manufacturers and semiconductor suppliers choose conductive EVA foam to address:

· Elimination of static buildup – Immediate charge dissipation prevents latent failures.

· Safe handling of exposed pins and contacts – Prevents arcing during transport.

· Consistent resistance values – Reliable performance in both humid and dry environments.

· Compatibility with cleanroom standards – Dust-free and non-contaminating packaging solution.

By comparison, anti static EVA foam may be better for general electronics packaging, but conductive EVA foam is essential when zero tolerance for static damage is required.

�� 4. Technical Highlights

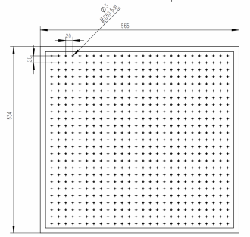

· Hardness: 38 Shore C (standard, customizable available)

· Color: Black

· Density: Custom per requirement

· Surface resistance: 10³–10⁶ Ω (permanent conductivity)

· Processing: CNC cutting, die-cutting, lamination, adhesive backing, insert fabrication

�� 5. Industry Value & Market Trend

The global demand for conductive EVA foam is increasing due to the growth of:

· AI semiconductor chips – requiring ultra-reliable ESD packaging foam solutions.

· 5G and high-speed optics – where optical modules must be transported in conductive carriers.

· Medical and laboratory instruments – ensuring safe packaging for diagnostic sensors.

As automation and robotics expand, conductive EVA foam will remain the premium choice for ESD packaging foam in high-value industries.

�� 6. Final Thought

When it comes to protecting semiconductors and optical devices, anti static EVA foam may not be enough. Only conductive EVA foam provides the low-resistance, permanent ESD protection required for the most sensitive applications.

At YUFA Polymer, we customize conductive EVA foam solutions to fit semiconductor trays, optoelectronic carriers, and robotics packaging systems.

�� Contact us today to discuss your ESD protection needs:

�� info@yufapolymer.com

�� www.yufapolymer.com